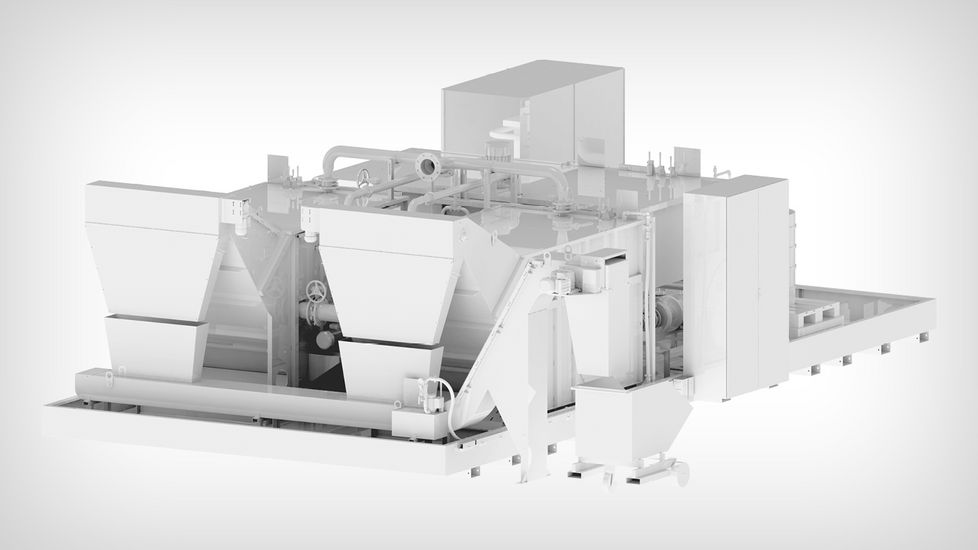

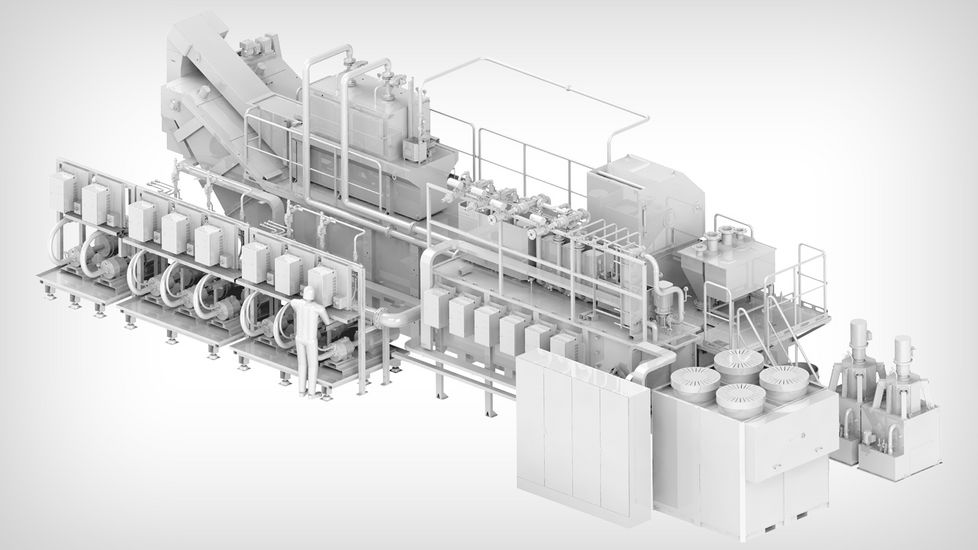

Double vacuum rotation filters with collecting conveyors for collective chip discharge.

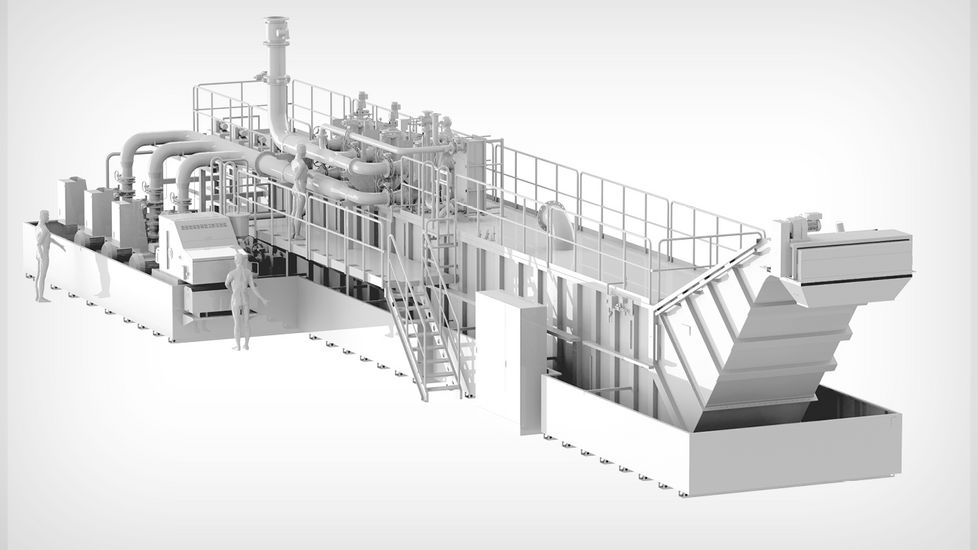

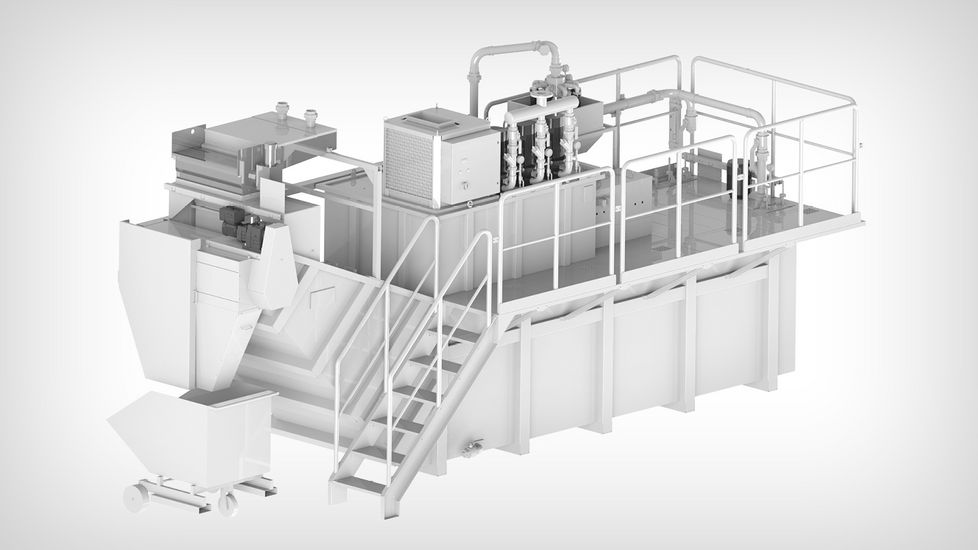

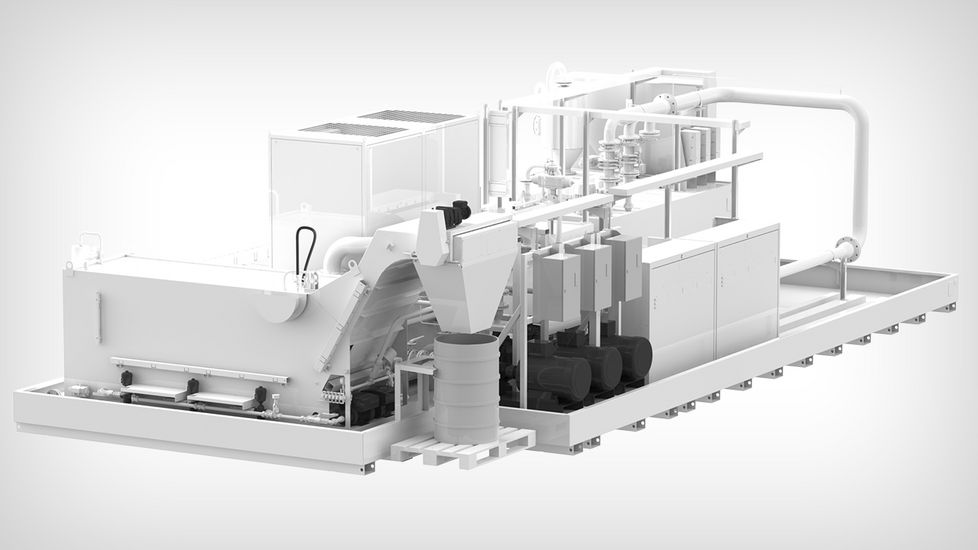

Central filter system with four sludge removal containers, regenerate treatment, and chip disposal.

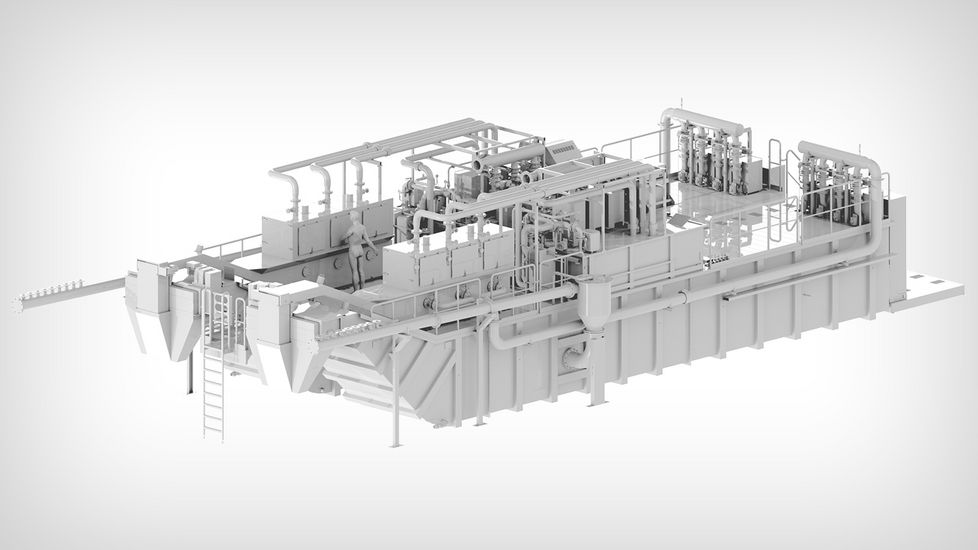

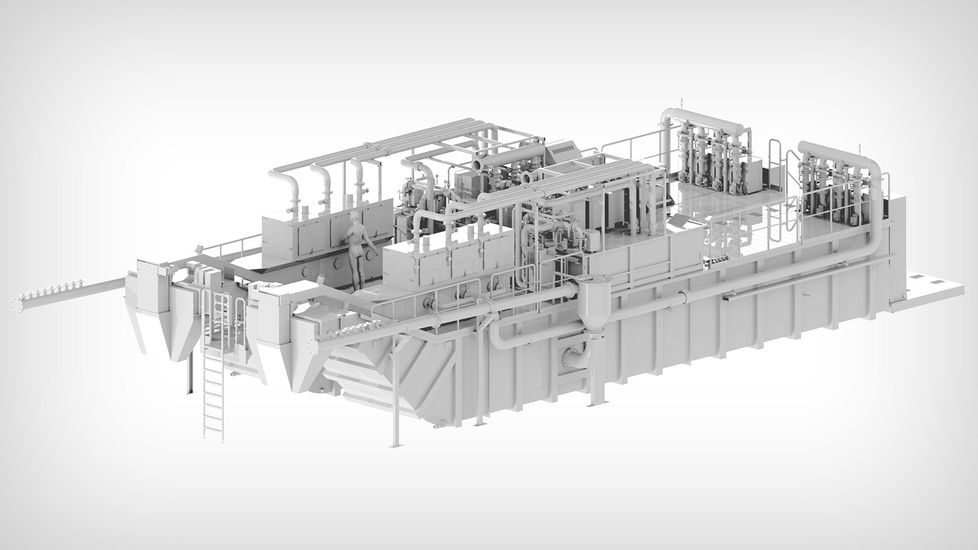

Central filter system with collecting conveyor for collective chip discharge.

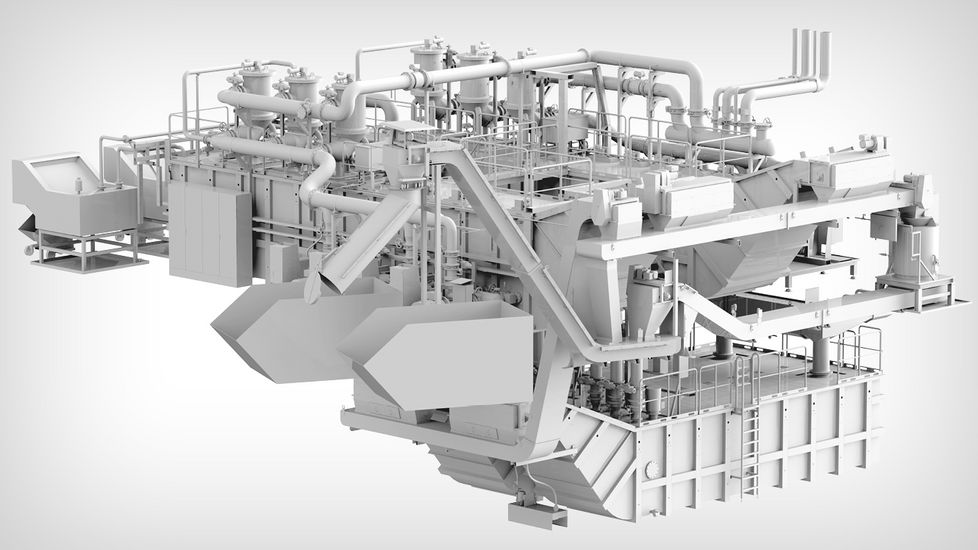

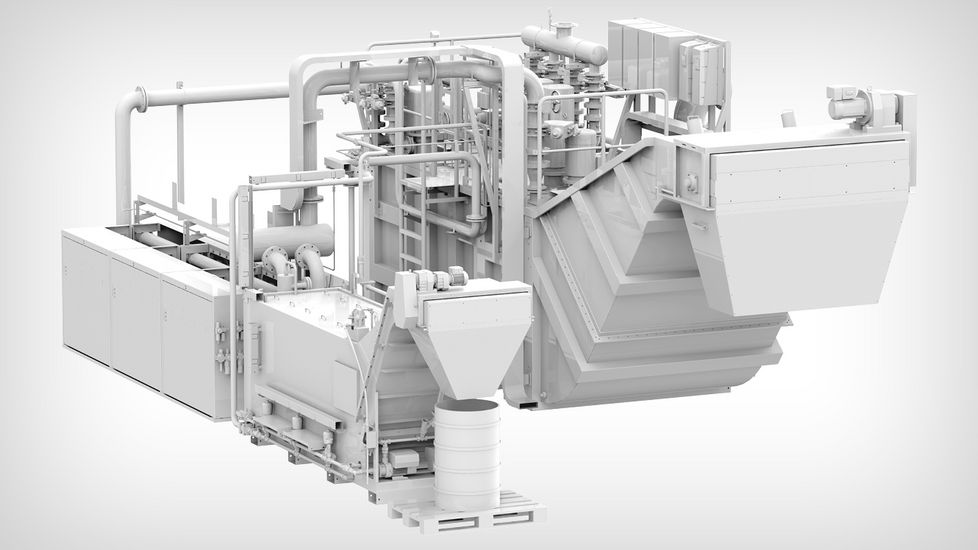

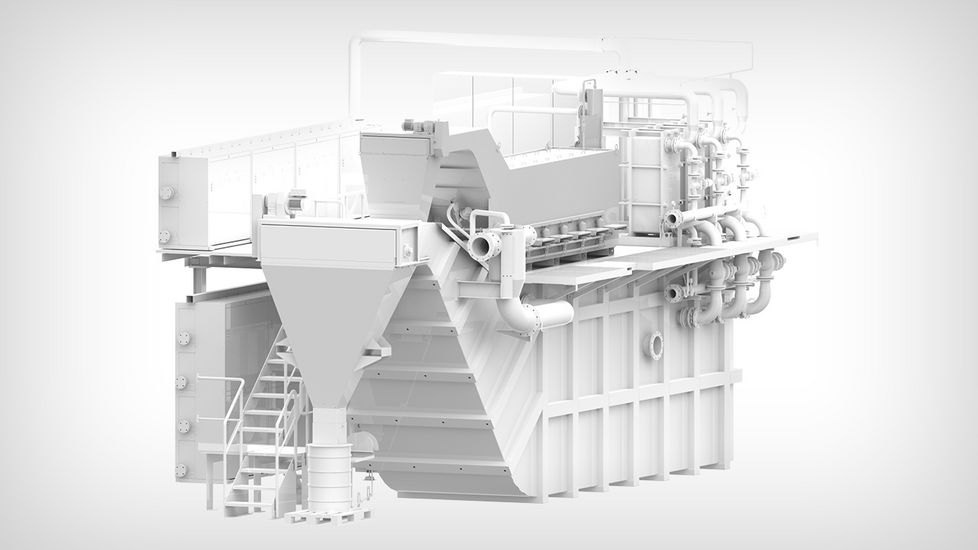

Chip separator and filtered fluid tank. In the first filter stage 100 µm, in the second filter stage 30 µm. Chip disposal via distribution conveyors to two truck containers.

Sedimentation container with scraper belt conveyor for chip pre-separation and inline filtration via reversible flow filters.

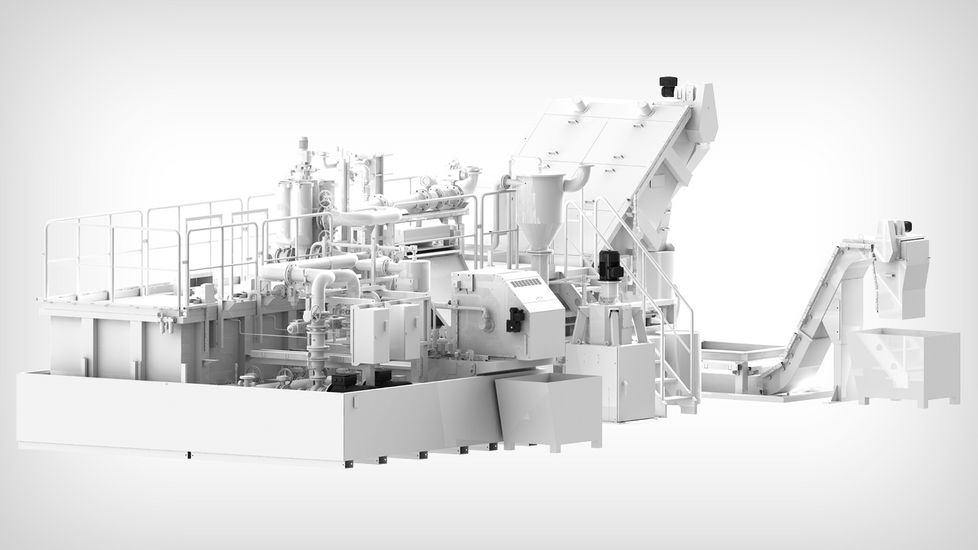

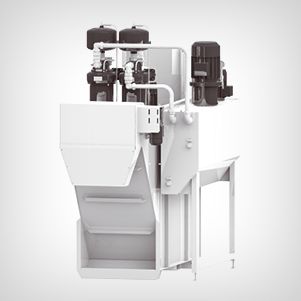

Sludge remover with magnetic roller for pre-separation. Compact belt filter KF 400 for desludging of the reversible flow filter. Scraper belt conveyor 500 K-3 set up under chip centrifuge. Fluid centrifuge CA 100 as bath care.

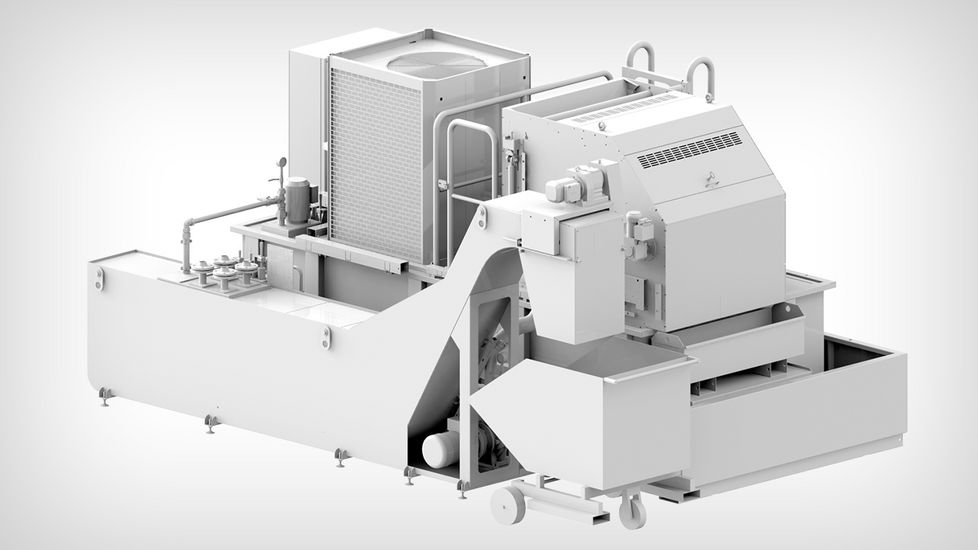

Chip conveyor for chip pre-separation and compact belt filter for filtration.

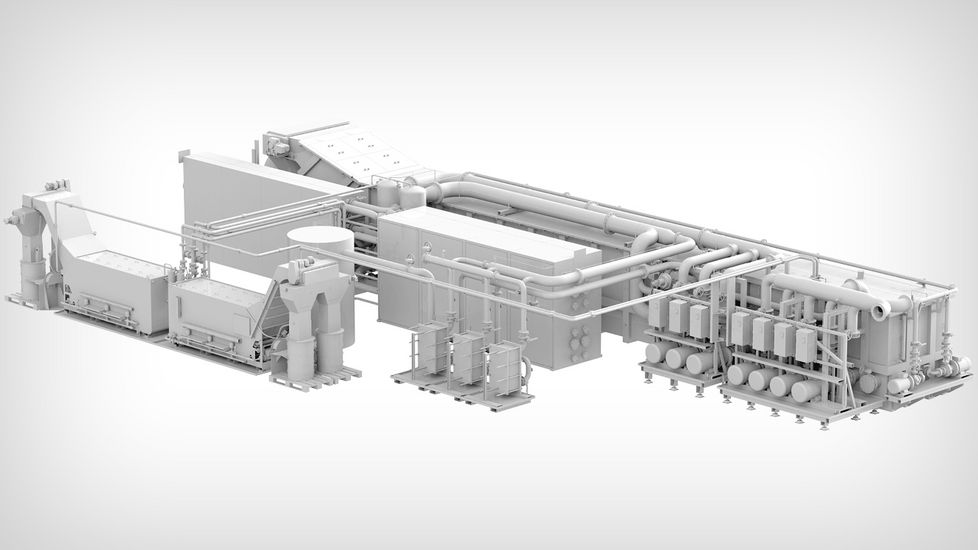

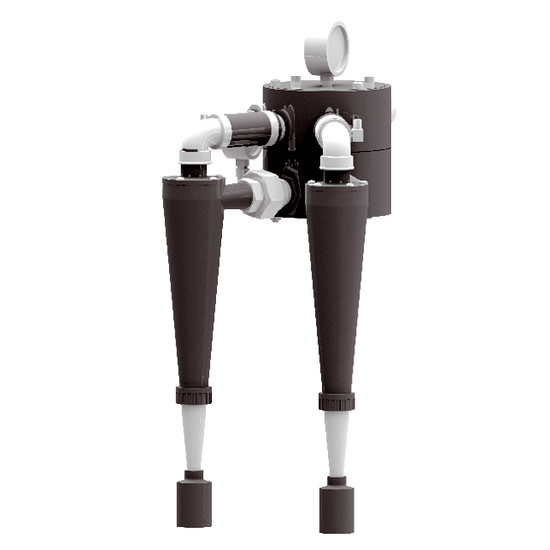

Central filter system with filtration via hydrocyclone units and compact filter as bypass filter.

Sedimentation container, hydrocyclone filtration, and fleece filter for the bath care.

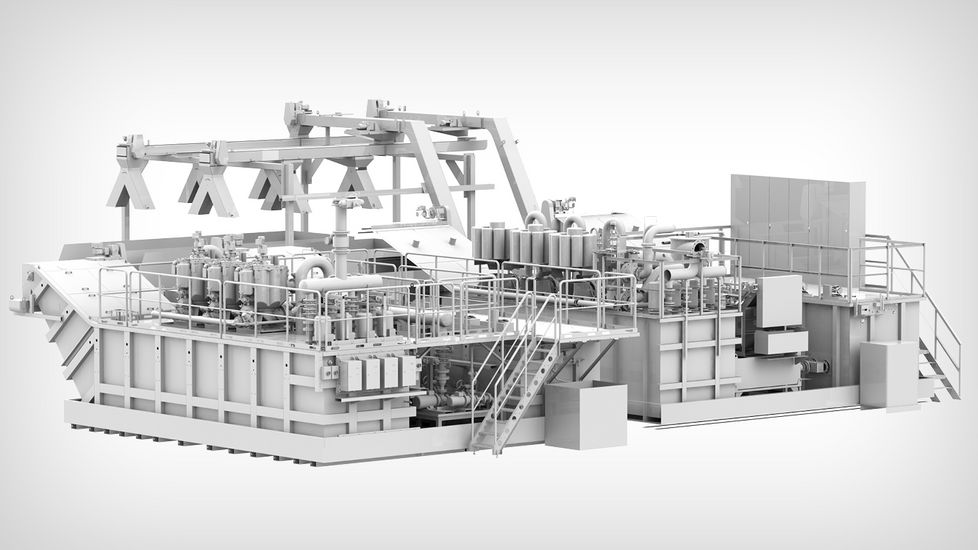

Sedimentation tank with desludger and magnetic roller for pre-separation. Main filtration via hydrocyclones and post-filtration via gravity belt filter.

Central filter system with desludger and automatic concentrator as automatic sludge filter.

Central superfine filter system with collecting container and two automatic concentrators as automatic sludge filter.

Superfine filter system with flat tank, in a safety catch pan.

Central superfine filter system with desludger in two-story design.