With our solutions, our customers can produce economically and with high process stability, flexibility and safety. Together with you, we plan a system that fits your installation.

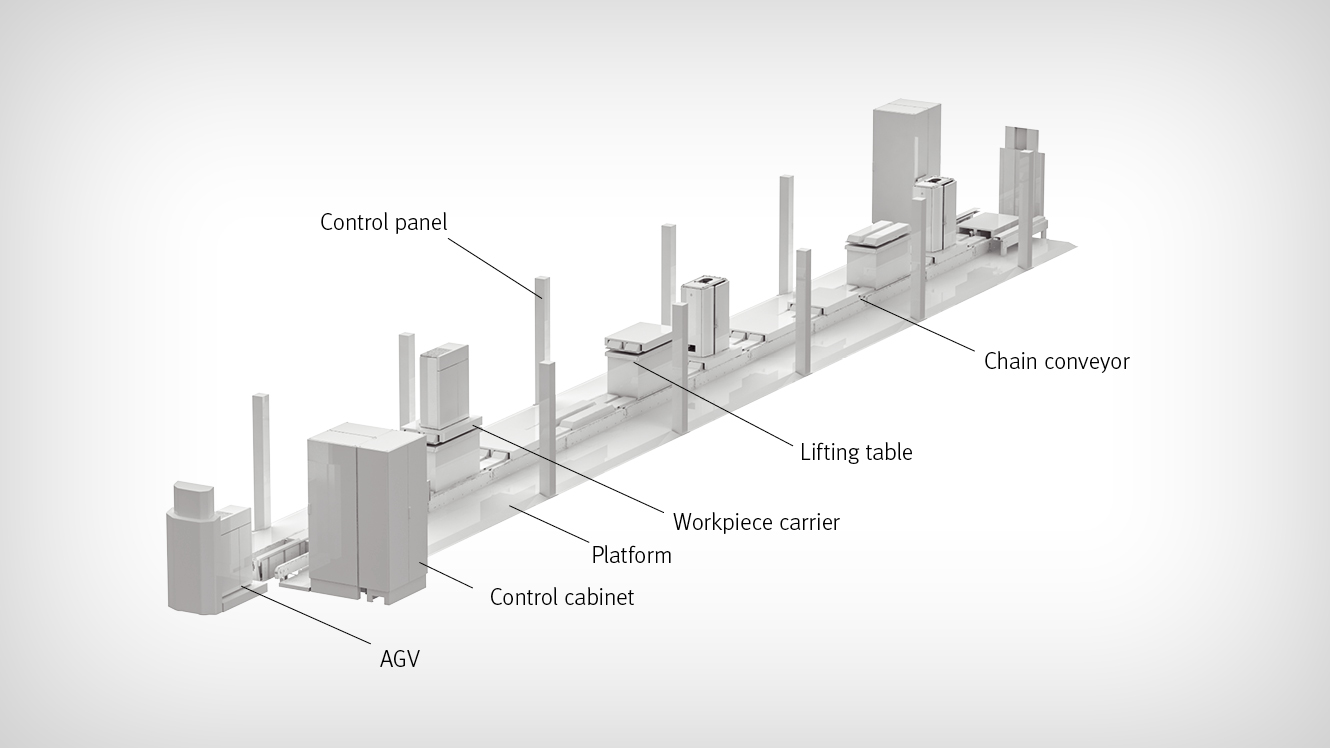

Automated Guided Vehicles (AGVs) deliver the stove bodies to the assembly line and then collect the finished assembled product. The automatic conveying of the products during assembly frees the assemblers from handling the heavy objects. With the new assembly line, the customer was able to increase their deliveries by about 20 % within one year.

• 40 different stove variants

• Separation of logistics and value creation

• Added value concentrated in the assembly line

• Exemplary occupational safety and ergonomics

• Investments in Industry 4.0 technologies

• Connection to MES system

• Material supply via AGV

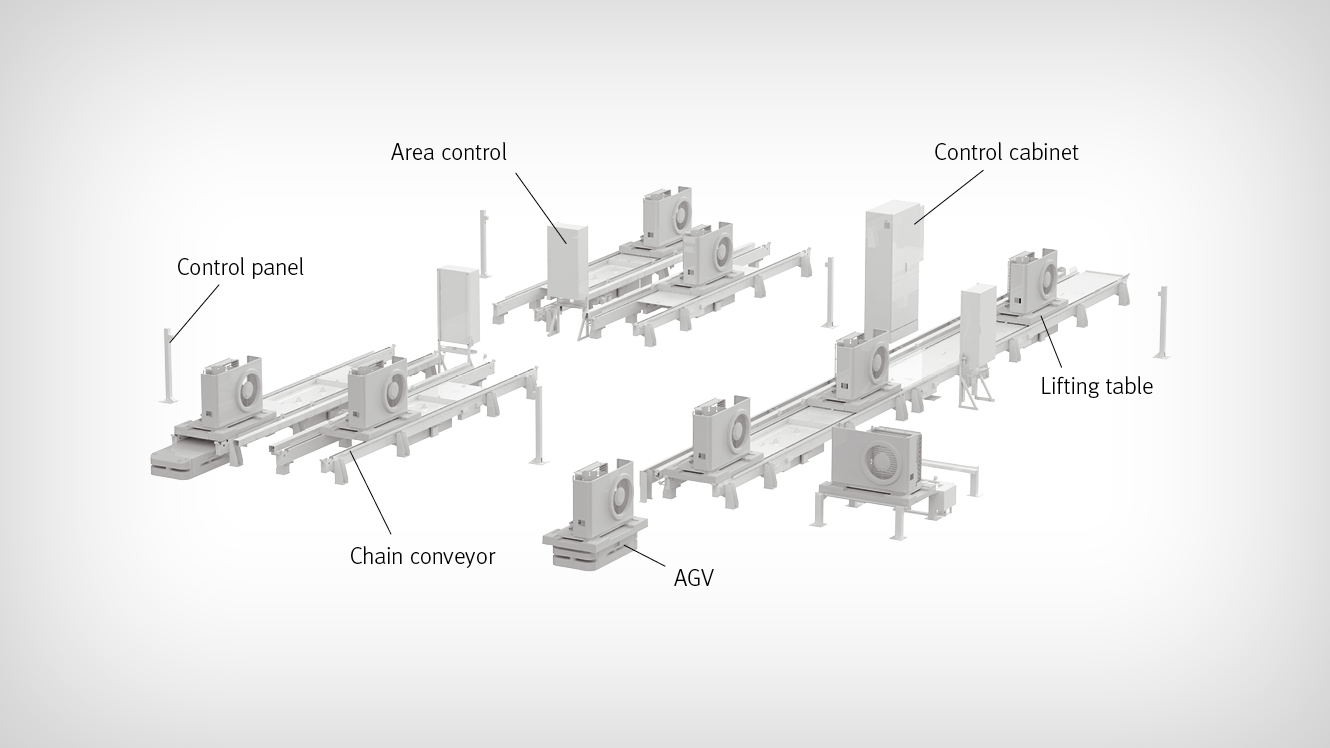

By using intelligent conveyor systems and AGVs, the customer was able to realise a highly flexible production line. Stationary conveyor lines with manual workstations are connected to individual work and inspection stations via AGVs. A head controller ensures that the different heat pump models find their individual ways to the required assembly stations. The output can be doubled on the same area using the same number of employees.

• 8 different product variants

• 100 identical workpiece carriers that are compatible with each product type

• Buffer rack for 64 workpiece carriers

• Universal assembly modules that are networked via an AGV

• Ergonomic assembly work stations

• Product tracking with feedback to the ERP system

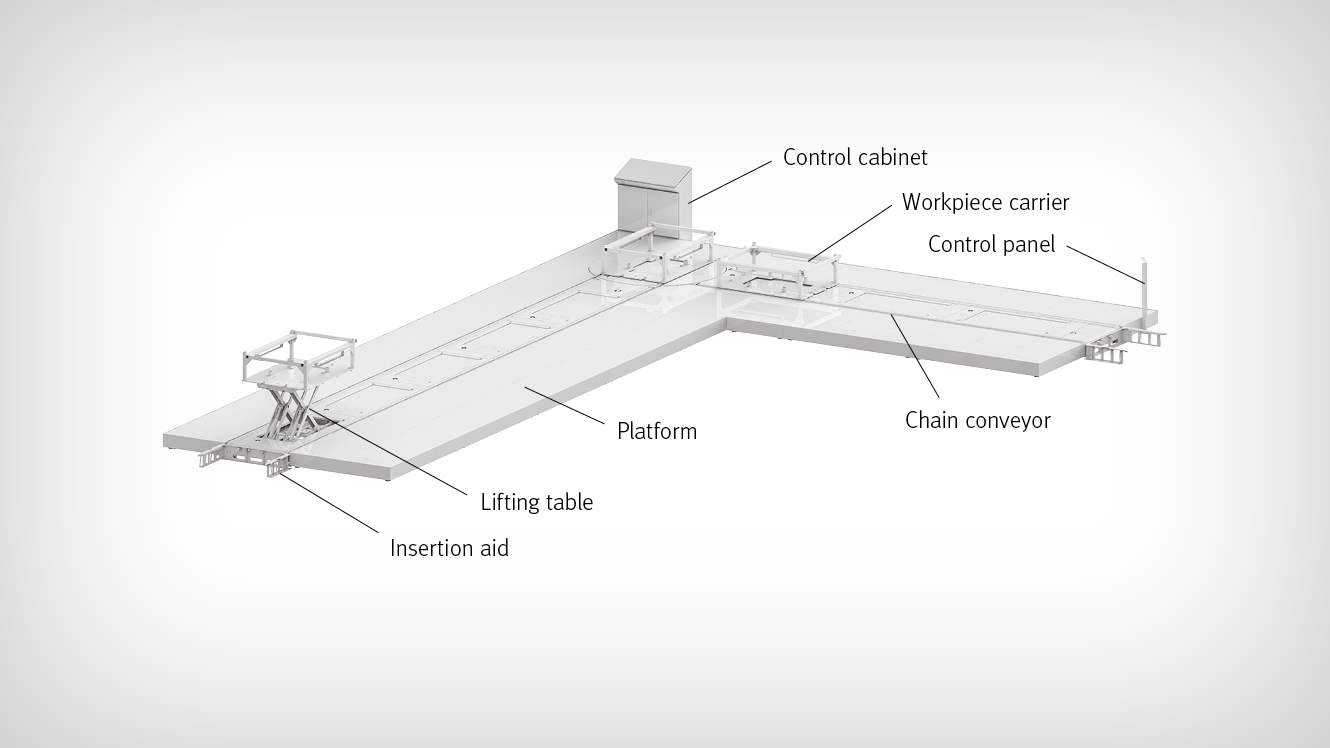

In order to make the assembly of the lithium-ion batteries employee-friendly and economical, the customer relies on floor-level conveyor technology as well as the combination of trolleys, workpiece and material carriers. The advantage of the assembly line is that the components can be transported from workstation to workstation without further intervention by the worker.

The lifting tables installed in the line are individually height-adjustable and rotatable. This saves time and is ergonomically beneficial for the employees. The now automated transport increased productivity by leaps and bounds.

• Forklift batteries in 120 variants

• Unit weight up to 3,000 kg

• Customer-specific workpiece holder

• Information transmission via RFID

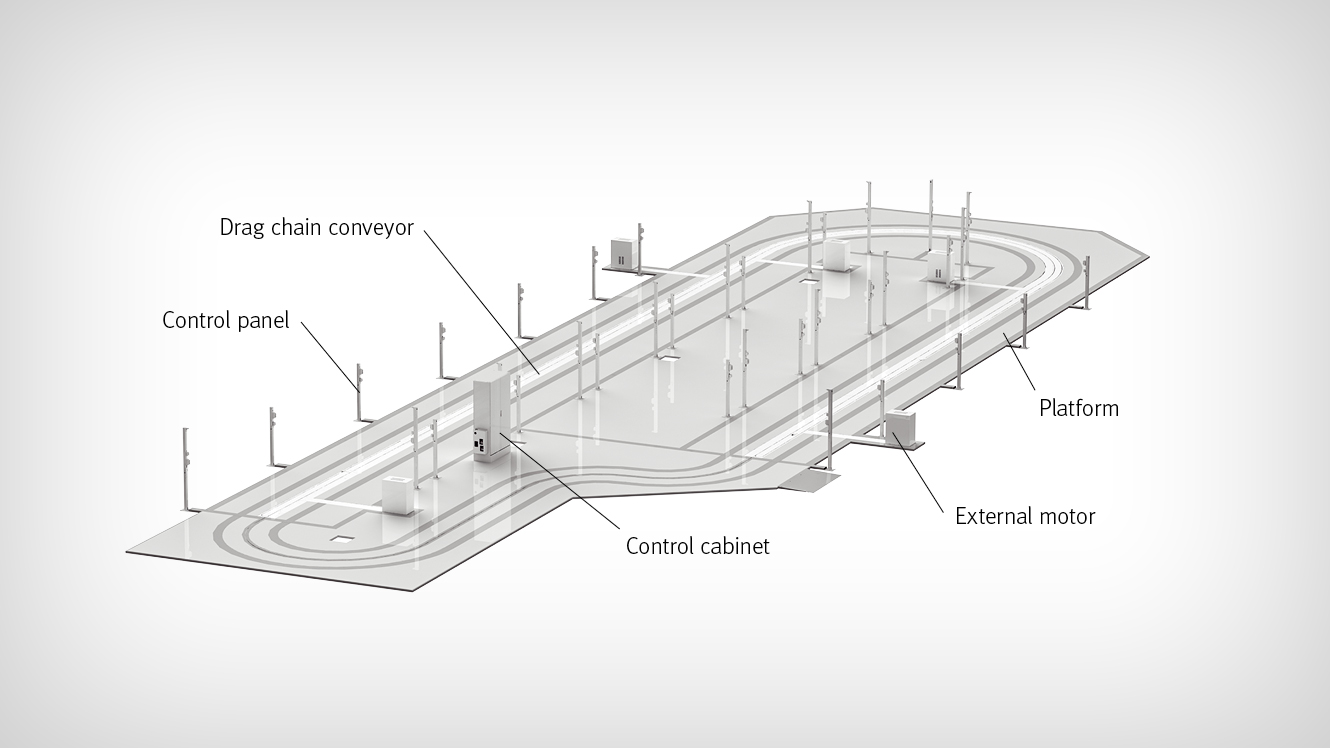

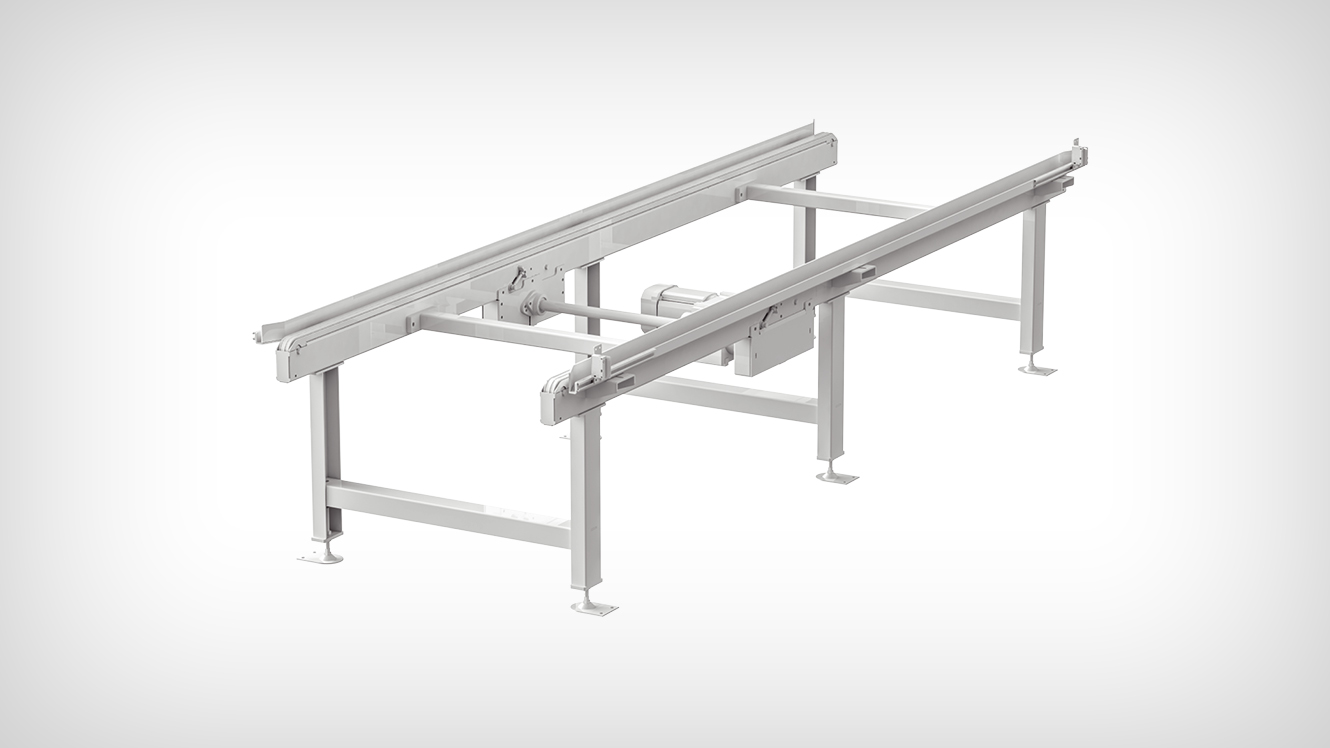

The customer's project managers attached great importance to robust technology, as is the case with a drag chain conveyor. Floor installations were not possible and the platform height was to be as low as possible. A pre-assembled assembly now leaves the conveyor every nine minutes.

• Weight of components 2.0 to 3.5 t

• Continuous conveying speed of 0.3 m/min

• Drag chain transport system

• Customer-specific assembly cart

• No structural measures required

• System height 60 mm

• Weight per cart up to 4 t

• Various operating modes possible (flow, clocked or mixed)

• Max. belt length: 6,000 mm

• Height: ≥ 230 mm

• Transport weight: accumulation roller chain 1,500 kg/m, straight link chain 4,000 kg/m

• Accumulation roller chain and straight link chain (maintenance-free upon request), ¾" duplex chain

• Accumulation of transport units possible

• Functional units: separator, backstop, indexing units, etc.

• Transport medium: trolley, workpiece carrier, pallet, pallet cage, special load carrier, etc.

• Max. belt length: 6,000 mm

• Height: ≥ 230 mm

• Transport weight: 3,000 kg/m

• Drive roller to roller

• Accumulation of transport units possible via friction roller

• Functional units: separator, backstop, indexing units, etc.

• Transport medium: workpiece carrier, pallet, pallet cage, special load carrier, etc.

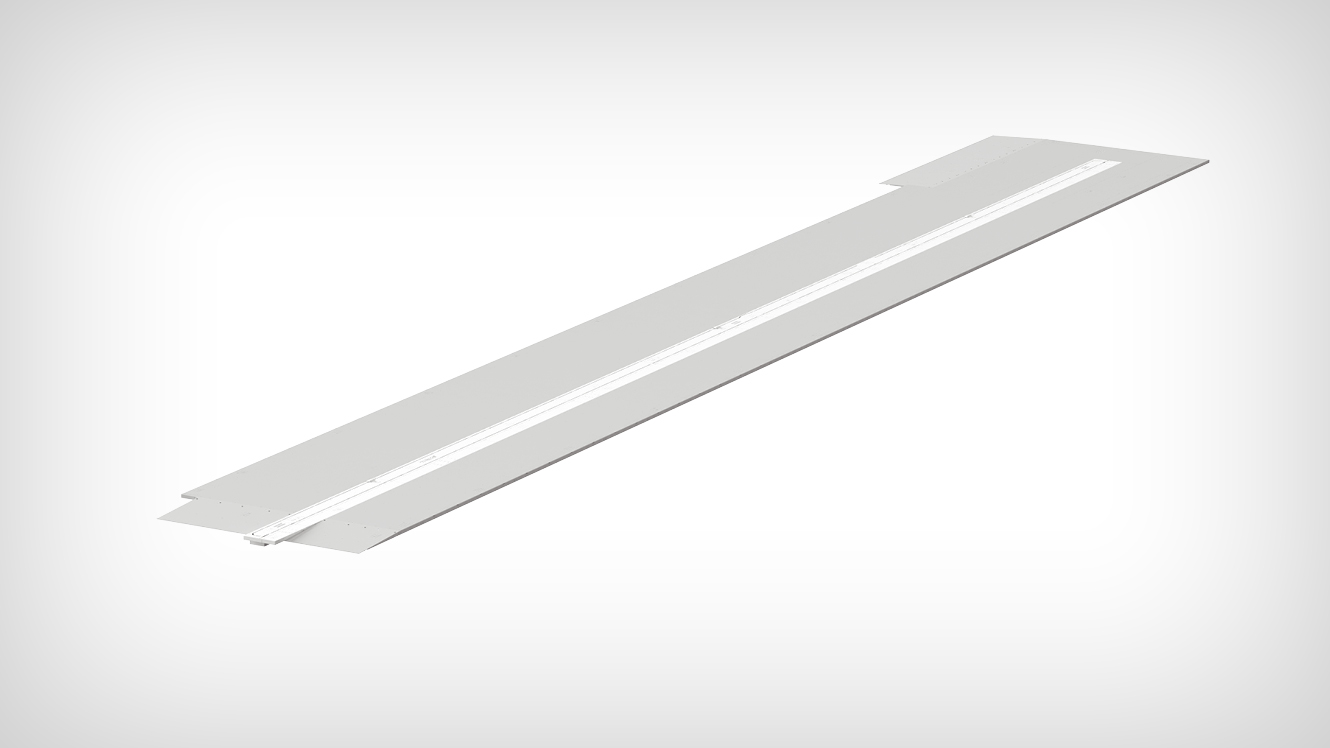

• Max. belt length: 50,000 mm - Extension via belt transfer

• Height: 60 mm

• Transport weight: max. 3,500 kg per trolley

• Drive arranged between chain strands

• Speed continuously adjustable

• Position control possible

• Master-slave combination possible with two drive strands

• Underfloor or overfloor

• Chain driver variably adjustable

• Trolley drive unit spring-loaded

• Decoupling from the tension strand via separator

• Transport medium: trolley

The demands placed on production today are diverse: Flexible production systems, different variants and efficiently scalable lot sizes. Matrix production as cycle-independent line production combines the flexibility of individual production with the economic benefits of classic line production.