Systems with pump technology

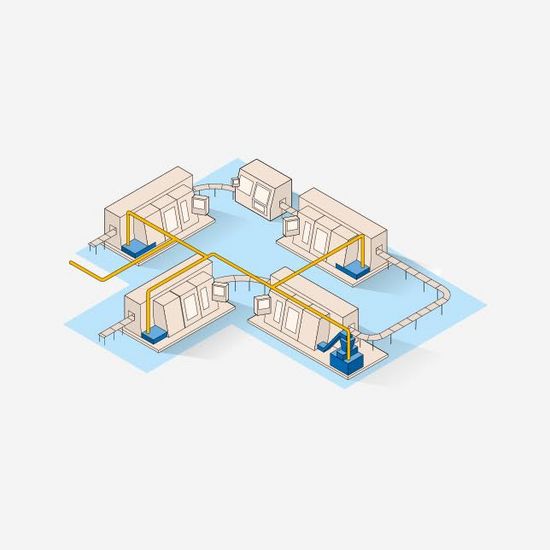

A conveyor and filter system with pump technology is suitable for fully-automatic chip transport from several processing machines to a central filter system. Cooling lubricant serves as the carrier medium.

If chips and/or cooling lubricants are transported completely automatically to a central point and should be treated there, system solutions are required. These are individual systems and components that are linked to form one system. KNOLL can offer you all required services, from planning to production to start-up, all from a single source. Then our customer service ensures safe and economical operation. And if the system should be expanded or reconfigured, KNOLL is the right partner for you.

A conveyor and filter system with pump technology is suitable for fully-automatic chip transport from several processing machines to a central filter system. Cooling lubricant serves as the carrier medium.

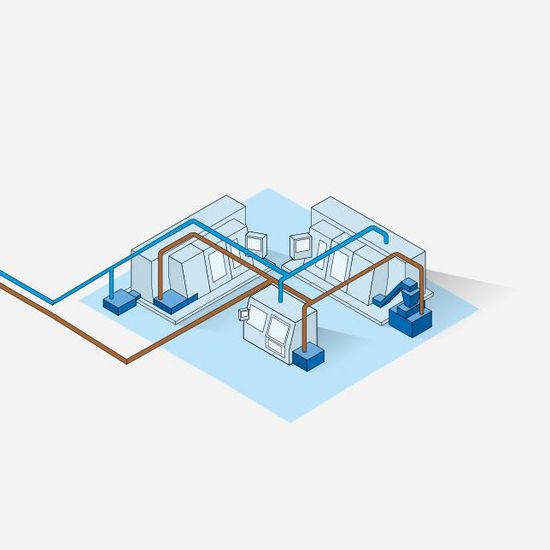

A conveyor system with extraction technology is suitable for fully-automatic chip transport from several processing machines to a central collection point. Room air serves as the carrier medium.

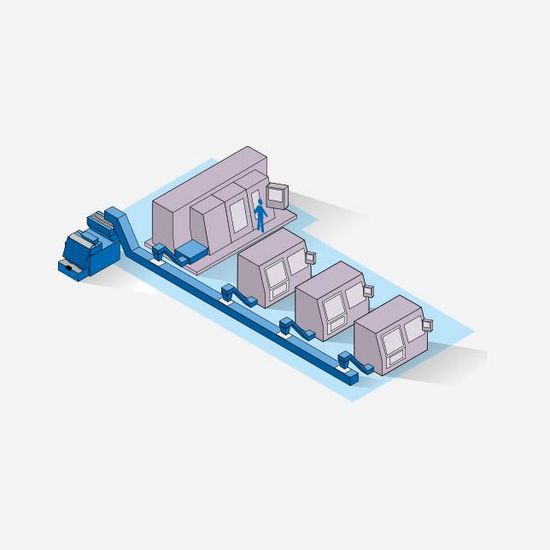

Collecting conveyor systems are required to bring metal chips and small parts from production to a central collection point.

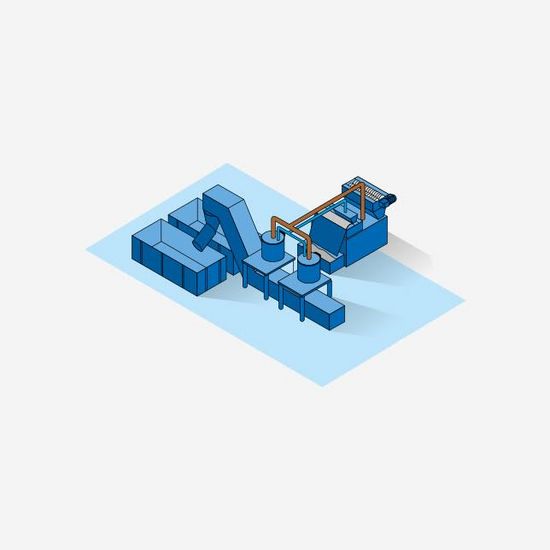

The treatment of chips has many advantages: they are dry and separated by type, so disposal costs are low. Depending on the material, it may even be possible to sell the chips.

We are suppliers of complete solutions and offer our customers the appropriate accessories for the KNOLL central systems: